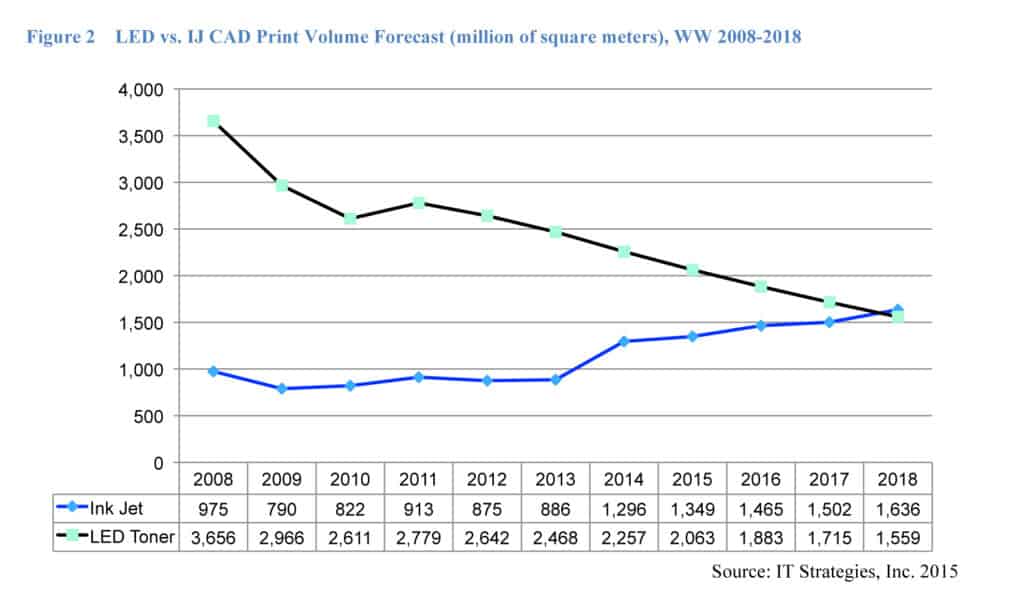

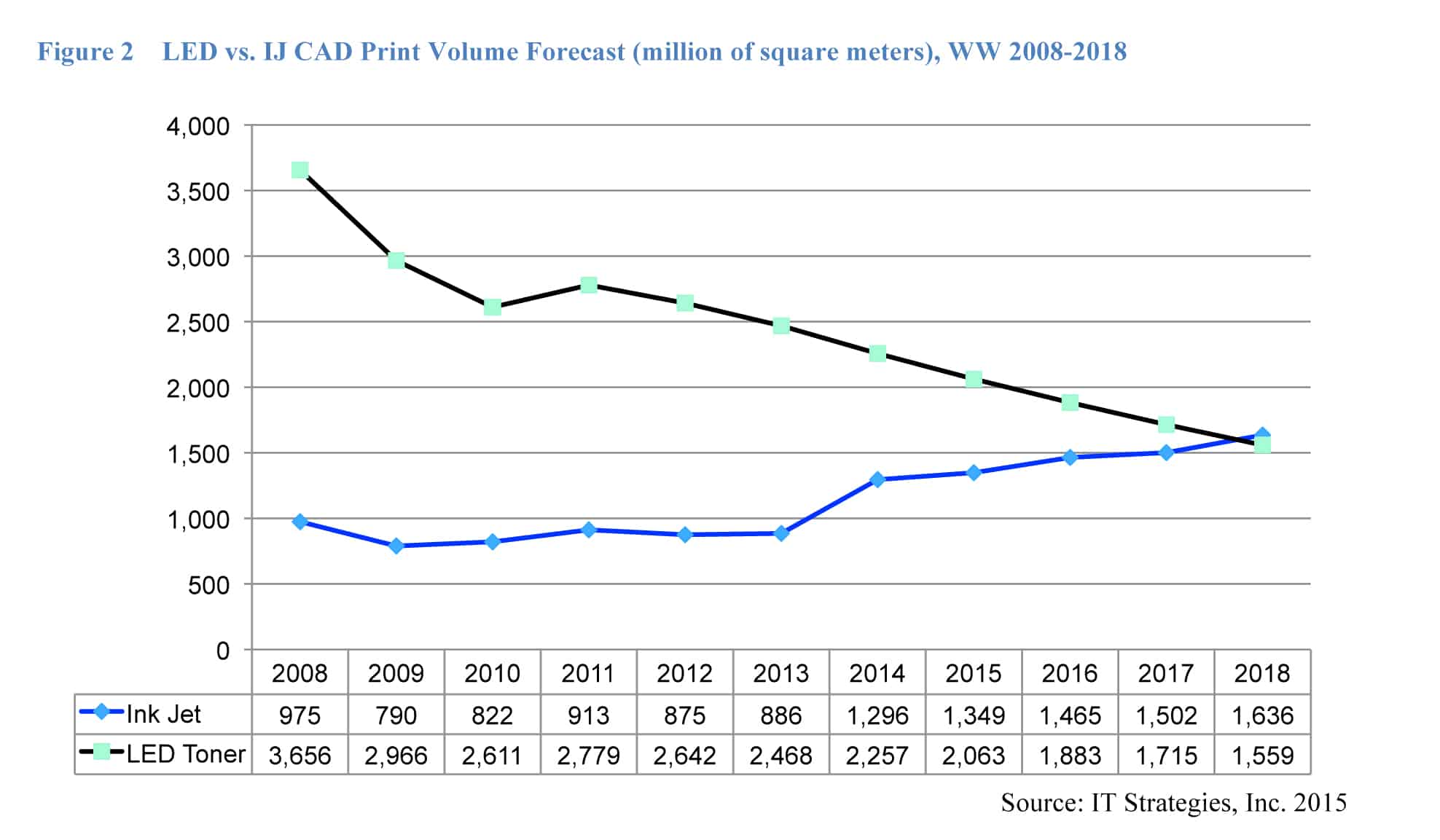

The technical drawing – also known as the computer aided design (CAD) – market for printing equipment took a dramatic downward turn in the 2008 economic recession. Approximately 70-80% of CAD output is used by Architects/Engineers/Construction, so the pressure upon the construction industry to become more efficient since the economic recession has never been stronger. While it has recovered somewhat in recent years, permanent changes have occurred in the habits of CAD print users and demand for printing technology. This change in printing technology is now revolutionizing the way commercial printers make their prices for AEC prints.

The new HP PageWide XL 5000 at Replica Printing Services has the ability to switch from monochrome to color drawings in an instant. This technology is bringing immediate savings to users in the reduction of costly mistakes made during the construction process due to misinterpretation of the technical drawing plans. With building and home designs becoming ever more complicated, mistakes were often made when the monochrome diagrams “hid” the details of specific infrastructure requirements. This printer is also what is allowing us to lower our color printing prices for line drawings. Other regions still lag in the adoption of color, mainly because of a perceived cost penalty for color print. With both the cost of color print declining, and the benefit of a reduction in construction mistakes becoming more transparent, the volume of color inkjet CAD output has steadily grown and is expected to surpass monochrome LED toner output within the next three years.

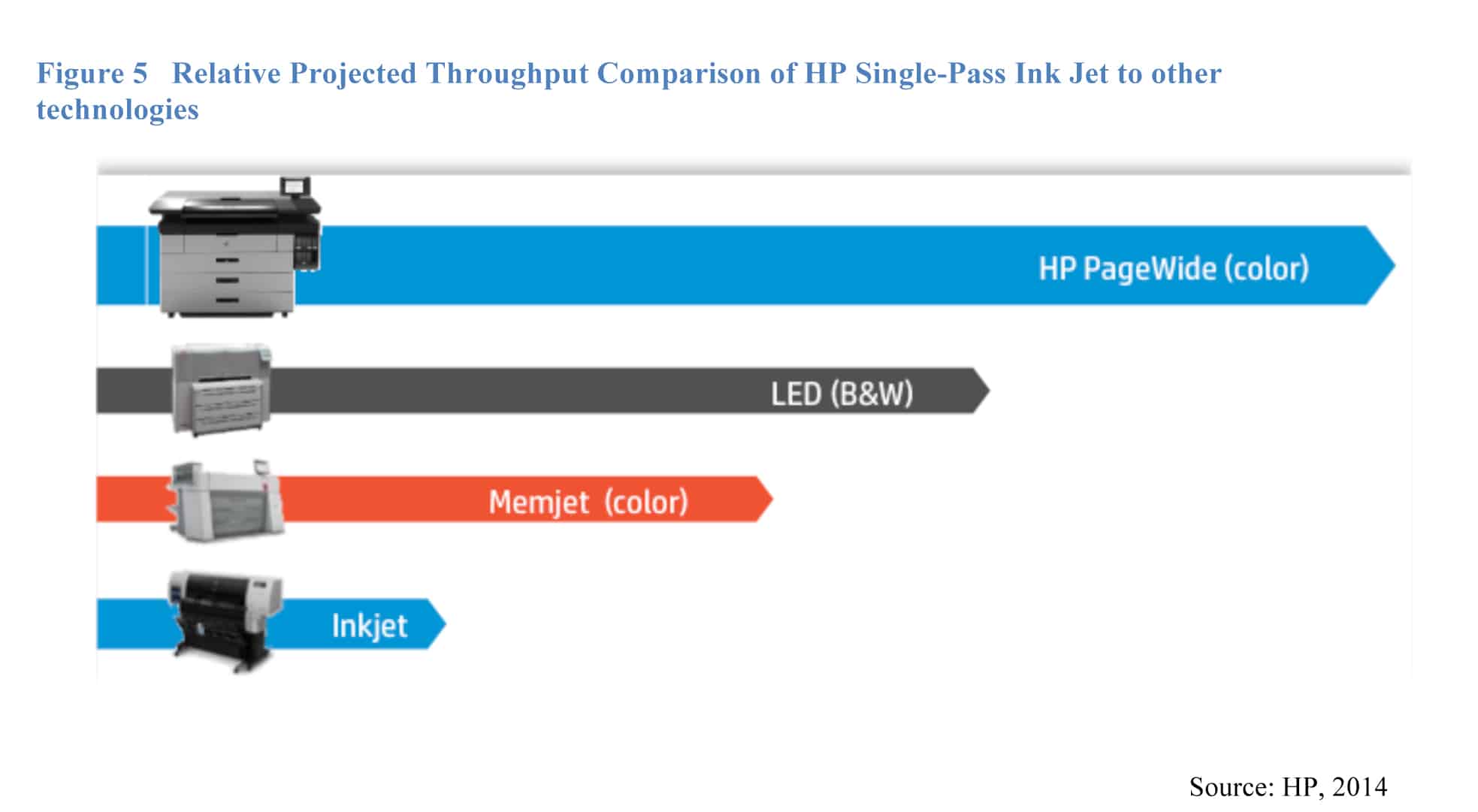

This graph shows the output of the HP PageWide XL compared to its closest competition.

This graph shows the output of the HP PageWide XL compared to its closest competition.

What is Driving the Investment Towards Inkjet Technology?

Printer manufacturers are investing in ink jet technology for a number of reasons, with the main reason the technology’s upside for further development and innovation. Once the core investment in printing technology is made, the print heads can be assembled into single-pass arrays. This enables ink jet printing systems at their extreme to print at speeds up to 300 linear meters per hour, at print widths ranging from the width of a page to up to 40 inches wide. Another reason is that inkjet technology has inherently fewer moving parts than toner print engine technology, making it simpler and more cost effective to develop color printing systems. Those color printing systems, when using pigmented color inks, create output that can be archived in storage with no fading for up to 200 years or more.

Aqueous single-pass ink jet technology is the single-most important development in HP’s printing business, based upon billions of dollars of investment. The reason for its importance is simple, due to its productivity advantages over scanning ink jet print heads, single-pass ink jet can now color match offset and outperform toner print technology in productivity at equal or better levels in output quality and durability.

This change in technology for the AEC community, has also lead to a potentially major change in commercial digital printing prices as well. No longer will prices be based on color or black and white ink. Color prices will now be much closer to that of black and white printing, and instead, the price of the print will now depend on what amount of ink coverage your print has regardless if it is color or black and white. The image below shows the different coverage types and how the price would increase as density increases.